Understanding Ceiling Insulation Between Floors

Definition and Purpose – What is ceiling insulation between floors and why it is essential for home comfort and energy efficiency

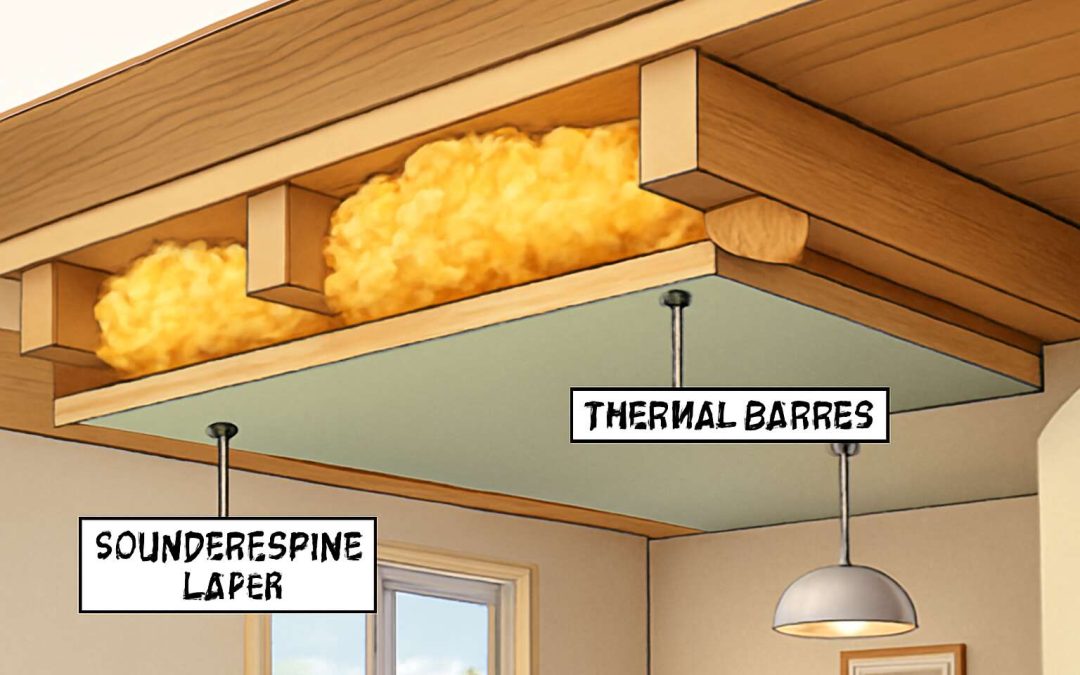

Imagine living in a home where the chill of winter or the scorching heat of summer feels like a distant memory. That’s the magic of effective ceiling insulation between floors! It’s a silent hero tucked away above your head, preventing heat from escaping during the cold South African winters and keeping unwanted warmth out during those blazing summer days. Without it, your home becomes a battleground of temperature swings, and your energy bills skyrocket faster than a Cape Town kite in a storm.

Ceiling insulation between floors isn’t just about comfort; it’s about smart energy use and reducing your carbon footprint. By creating a thermal barrier, it helps maintain consistent indoor temperatures, making sure your living space stays cozy without constantly firing up the heater or aircon. Plus, it minimizes noise transfer—so you can finally enjoy your Netflix marathon in peace or have a quiet conversation without your upstairs neighbor’s karaoke session interrupting.

In essence, ceiling insulation between floors transforms your home into an energy-efficient sanctuary, proving that sometimes, the best solutions are tucked just above your ceiling! Whether you’re battling winter chills or summer sizzles, it’s an investment worth considering for a more comfortable, cost-effective lifestyle.

Types of Insulation Materials – Different materials used for ceiling insulation between floors including fiberglass, spray foam, cellulose, and mineral wool

When it comes to enhancing the thermal integrity of your home, the choice of materials for ceiling insulation between floors is pivotal. Each option offers unique benefits, from cost-effectiveness to superior insulating properties, shaping the comfort and energy efficiency of your living space. Fiberglass, a popular choice, boasts excellent thermal resistance and durability, making it perfect for creating a reliable barrier against heat loss in South African winters. Spray foam, on the other hand, offers seamless coverage and impressive air sealing capabilities, transforming your ceiling into an impenetrable fortress against unwanted drafts.

Cellulose insulation, crafted from recycled paper, combines eco-friendliness with high insulating performance. Its dense texture minimizes noise transmission, a bonus for homes where tranquility is treasured. Mineral wool, also known as rock wool, is fire-resistant and highly soundproof, making it an ideal material for those seeking both safety and serenity.

- Fiberglass

- Spray foam

- Cellulose

- Mineral wool

Each of these materials can significantly elevate the effectiveness of ceiling insulation between floors, allowing homeowners to tailor their approach based on budget, climate, and specific needs. The versatility of these options ensures that every South African home can achieve the perfect balance of comfort and efficiency, transforming mere ceilings into shields against nature’s extremes.

Key Benefits – Thermal regulation, soundproofing, and increased property value

In the world of home comfort, ceiling insulation between floors acts as a silent guardian, weaving warmth and tranquility into the very fabric of your living space. Its most enchanting benefit is thermal regulation—keeping your South African home cozy during chilly winters and cool when the sun blazes outside. This natural barrier reduces the need for constant heating and cooling, translating into lower energy bills and a smaller carbon footprint.

But the magic doesn’t stop there. Soundproofing is a vital aspect, transforming your home into a sanctuary of serenity. Whether it’s muffling footsteps above or creating a peaceful retreat from noisy neighbors, ceiling insulation between floors acts as a whispering shield against unwanted noise. For homeowners seeking to elevate their property’s value, this upgrade is an investment that pays dividends—adding a layer of sophistication and efficiency that appeals to future buyers.

Beyond comfort and tranquility, insulation enhances the overall integrity of your home, making it more resilient against the harsh South African climate. This layered protection not only shields against temperature extremes but also fortifies your property’s worth—turning your ceilings into enchanted barriers that safeguard your sanctuary from the elements and the test of time.

Factors to Consider Before Installing Ceiling Insulation

Building Regulations and Insulation Codes – Understanding local building standards and requirements

In the shadowed corridors of home design, the choice to install ceiling insulation between floors is shrouded in more than mere necessity—it’s a ritual of preservation against the creeping dampness of chaos. Yet, before the first roll of insulation is laid, a meticulous understanding of building regulations and insulation codes becomes imperative. South Africa’s stringent standards serve as a silent guardian, ensuring the delicate balance between safety, efficiency, and the whispering echoes of the past.

Building regulations dictate not only the materials permissible but also the installation techniques that must be adhered to, safeguarding inhabitants from the unseen perils of fire and mould. Compliance isn’t just a legal obligation; it’s a pact with the very fabric of safety and sustainability. Insulation codes, often cloaked in technical jargon, demand that every layer of ceiling insulation between floors aligns with energy efficiency standards—an unyielding decree that transforms a simple upgrade into a shield against the relentless passage of heat and sound.

Beware the labyrinth of local standards—each region within South Africa might whisper different requirements, demanding the discerning eye of a professional who respects these unseen but vital rules. Only through understanding these intricate standards can one ensure that the insulation not only whispers its thermal secrets but also stands resilient against the ghostly march of time.

Existing Insulation and Structure – Assessing current insulation levels and ceiling construction

Before embarking on the journey of installing ceiling insulation between floors, it is crucial to scrutinize the existing insulation and structural integrity of your ceiling. Often, overlooked layers of insulation or structural anomalies can undermine the entire effort, rendering the upgrade ineffective or even hazardous. A thorough assessment reveals whether your current setup aligns with the desired thermal and acoustic objectives.

Understanding the current state involves examining the depth, type, and condition of existing insulation. If the insulation is compressed, water-damaged, or outdated, it may need removal or supplementation. Equally important is inspecting the ceiling construction—materials like suspended ceilings, plasterboard, or timber joists influence the choice of insulation material and installation technique.

In some cases, the structure may contain hidden obstacles or irregularities—wiring, pipes, or beams—that demand careful navigation. This detailed evaluation ensures that the installation of ceiling insulation between floors not only complies with building standards but also maximizes performance. Remember, the integrity of your ceiling’s structure is the silent foundation on which thermal comfort and energy efficiency depend.

Climate and Weather Conditions – Adapting insulation choices to specific environmental factors

Climate and weather conditions wield an often underestimated influence over the efficacy of ceiling insulation between floors. In South Africa’s diverse climate zones—ranging from the temperate coastal regions to the arid interior—the choice of insulation material must be carefully tailored to withstand specific environmental challenges. High humidity, for instance, necessitates moisture-resistant options like mineral wool, which resists mold and decay, ensuring the longevity of your insulation investment.

Conversely, in colder regions, superior thermal performance becomes paramount, prompting the selection of dense spray foam or thick fiberglass insulation. The fluctuating temperature extremes can compromise lesser materials, leading to compression, settling, or diminished insulating properties. A nuanced understanding of these climatic nuances ensures that ceiling insulation between floors is not only effective but resilient against South Africa’s capricious weather patterns.

- Assess local climate conditions and their impact on insulation performance.

- Choose materials that resist moisture and temperature fluctuations.

- Consider ventilation and airflow to prevent condensation and heat loss.

Ultimately, adapting your ceiling insulation between floors to the environment transforms a simple upgrade into a strategic shield—preserving comfort, reducing energy bills, and respecting the building’s structural integrity amidst South Africa’s climatic tapestry.

Budget and Cost Implications – Calculating installation costs and long-term savings

Cost considerations for ceiling insulation between floors often catch homeowners off guard. While the initial investment can seem substantial, the long-term savings on energy bills make it a strategic decision rather than just an expense. In South Africa’s fluctuating climate, choosing the right insulation material involves balancing upfront costs with durability and performance. High-quality options like spray foam or mineral wool may be pricier initially, but their resilience against moisture, pests, and temperature extremes ensures a longer lifespan and consistent thermal regulation.

Understanding the true cost of installation requires evaluating factors such as ceiling accessibility, existing insulation, and required material density. It’s essential to factor in potential structural modifications or upgrades, which can influence overall expenses. Moreover, some suppliers and installers offer packaged deals that include assessment, insulation installation, and aftercare, which can significantly reduce costs.

Ultimately, investing in ceiling insulation between floors is a calculated move—one that can slash energy bills and elevate comfort. When considering the budget, remember that the savings over time often outweigh the initial expenditure, turning your home into a fortress against South Africa’s capricious weather. The key is to select materials that deliver maximum thermal performance and longevity, ensuring your investment pays dividends well into the future.

Installation Methods for Ceiling Insulation Between Floors

Batt and Roll Insulation Installation – Step-by-step process of installing fiberglass or mineral wool batt insulation

Installing ceiling insulation between floors using batt and roll insulation is a straightforward process that can significantly improve a home’s thermal efficiency and soundproofing. This method involves placing fiberglass or mineral wool batts directly into the ceiling cavity, creating a barrier that reduces heat transfer and dampens noise between levels. The key is ensuring the batts fit snugly without gaps or compression, which can compromise their insulating properties.

Begin by carefully measuring the ceiling space to determine the correct batt size. Next, lay the insulation batts between the ceiling joists, making sure they are flush and properly supported. For added stability and to prevent sagging over time, some installers use wire supports or netting. It’s essential to wear protective gear — fiberglass particles can irritate the skin and eyes. Proper installation not only maximizes the effectiveness of the ceiling insulation between floors but also ensures compliance with local building standards.

For larger projects, it can be helpful to follow a systematic approach:

- Clear the ceiling area of any obstructions or existing insulation that may hinder installation.

- Secure the batts in place, ensuring they are tightly fitted between the ceiling joists.

- Seal any gaps around the edges with appropriate insulation tape or foam to prevent drafts and heat loss.

This method offers a cost-effective way to enhance energy efficiency and comfort within the home, making ceiling insulation between floors an investment worth considering for South African homeowners seeking sustainable living solutions.

Spray Foam Insulation Application – Advantages and installation tips for spray foam insulation

Spray foam insulation application stands out as a revolutionary method for achieving superior thermal regulation in homes. Unlike traditional materials, spray foam conforms seamlessly to every nook and cranny of the ceiling cavity, creating an airtight barrier that minimizes heat transfer and enhances soundproofing. This method is especially advantageous in South Africa’s diverse climate, where fluctuating temperatures demand adaptable solutions.

One of the most compelling advantages of spray foam insulation for ceiling insulation between floors is its exceptional R-value per inch, which translates into energy savings and increased comfort. Additionally, spray foam acts as a formidable moisture barrier, preventing issues like mould and dampness that can compromise structural integrity over time.

Proper installation is crucial to unlock these benefits. It’s recommended to follow a systematic approach that includes ensuring the ceiling cavity is free of obstructions and existing insulation that might hinder the foam’s adhesion. A professional application guarantees even coverage and optimal expansion, which is vital for achieving maximum efficiency. For those considering this method, it’s wise to be mindful of the following:

- Ensure the space is well-ventilated during application to manage fumes safely.

- Use high-quality spray foam products designed for ceiling insulation between floors to meet local building standards.

- Engage certified installers with experience in spray foam application to prevent common pitfalls such as over-expansion or incomplete coverage.

Ultimately, spray foam insulation offers a profound transformation in how homes maintain internal temperature and sound isolation. When applied correctly, it elevates the very essence of living comfort—an investment that resonates well beyond initial costs, especially in the context of South Africa’s unique environmental demands.

Blown-In Insulation Technique – Process and benefits of cellulose or fiberglass blown-in insulation

In the shadowed corridors of home insulation, the blown-in technique emerges as a whisper of innovation, cloaked in the quiet promise of thermal mastery. For those seeking an unobtrusive yet potent solution for ceiling insulation between floors, cellulose or fiberglass blown-in insulation offers a compelling choice. This method involves dispersing fine particles of cellulose or fiberglass into the ceiling cavity, filling every crevice, nook, and cranny with a dense, insulating embrace.

The process begins with a thorough assessment of the ceiling space, ensuring it’s free of obstructions and old insulation. A specialized hose then sprays the loose-fill material, which quickly settles into an even layer, conforming flawlessly to the existing structure. This technique not only enhances thermal regulation but also bolsters soundproofing—transforming the space into a sanctuary against the cacophony of the outside world.

Among the many benefits of blown-in ceiling insulation between floors are its exceptional ability to fill irregular spaces and its cost-effective nature. As the particles settle, they create a seamless barrier that resists heat transfer, making it an attractive choice for South African homes facing fluctuating climate conditions. Such insulation also adds to the property’s value, elevating comfort while adhering to local building standards. Whether you choose cellulose for its eco-friendly qualities or fiberglass for its durability, the blown-in method delivers a profound transformation—an invisible guardian for your home’s interior realm.

DIY vs Professional Installation – When to consider professional services and safety precautions

When it comes to installing ceiling insulation between floors, the choice between DIY methods and professional services can significantly impact the outcome. While a DIY approach might seem tempting for budget-conscious homeowners, it’s crucial to recognize the potential pitfalls—especially when safety is at stake. Proper installation ensures maximum thermal efficiency and soundproofing, but mishandling insulation materials can lead to hazards like respiratory issues or fire risks.

If you decide to take the DIY route, always wear protective gear—gloves, masks, and goggles—and follow manufacturer instructions meticulously. However, for those unfamiliar with insulation techniques or working within complex ceiling structures, enlisting professional installers is wise. They bring expertise, specialized tools, and an eye for detail that guarantees your ceiling insulation between floors performs at its peak.

- Assess the existing ceiling structure thoroughly.

- Choose the right insulation material for your climate and budget.

- Ensure the area is free of obstructions and old insulation before installation.

Professional installers also understand local building regulations and safety standards, which is vital for compliant and long-lasting ceiling insulation between floors. Whether opting for blown-in cellulose or fiberglass batt insulation, expertise ensures optimal coverage and avoids common pitfalls like gaps or compressed areas. Ultimately, knowing when to call in the experts can make all the difference in transforming your home into an energy-efficient haven.

Best Practices for Effective Ceiling Insulation

Barrier and Vapor Retarder Installation – Ensuring proper vapor barriers to prevent moisture issues

When it comes to ceiling insulation between floors, ensuring the proper installation of vapor barriers is often the unsung hero—yet it can make or break your thermal fortress. Moisture lurking in hidden corners is not just a minor inconvenience; it’s a sneaky saboteur that can lead to mold, wood rot, and a hefty repair bill. Proper vapor retarder installation acts as a moisture gatekeeper, preventing humid air from infiltrating your carefully insulated cavity and turning your home into a damp disaster zone.

To keep moisture issues at bay, it’s crucial to use high-quality vapor barriers, correctly positioned to face the warm side of the ceiling insulation between floors. Seal all joints meticulously—think of it as giving your vapor barrier a tight, moisture-proof hug. A good practice is to overlap seams by at least 10 centimeters and secure them with durable tape designed for insulation purposes. Remember, a poorly installed vapor barrier is like a leaky boat—no matter how good your ceiling insulation between floors is, water will find its way in.

For optimal results, consider the climate and weather conditions of your South African locale. In moist coastal areas, a thicker or more resilient vapor barrier might be necessary, whereas drier inland regions could get away with a simpler setup. Always adhere to local building regulations and insulation codes—skimping here can lead to penalties or, worse, structural issues. Proper barrier and vapor retarder installation isn’t just about compliance; it’s about safeguarding your comfort and property for years to come. After all, a well-sealed ceiling insulation between floors is the backbone of a truly energy-efficient and moisture-resistant home.

Sealing Gaps and Voids – Enhancing insulation performance by sealing leaks

Sealing gaps and voids in your ceiling insulation between floors isn’t just a minor detail—it’s the secret ingredient to unlocking peak insulation performance. Imagine your home’s thermal fortress being only as strong as its weakest link. Even the tiniest crack or unsealed seam can allow warm air to escape and moisture to sneak in, undermining your efforts. The art of effective sealing transforms your ceiling insulation between floors into an impenetrable barrier against the elements.

To truly enhance your insulation’s efficiency, meticulous sealing is essential. Use high-quality, durable tape designed specifically for insulation to secure all seams. An effective approach involves overlapping joints by at least 10 centimeters, creating a continuous shield that prevents leaks. Paying close attention to corners, edges, and penetrations—such as light fixtures and plumbing—is crucial in eliminating hidden pathways for air and moisture infiltration.

For optimal results, consider adopting a systematic sealing process. Start by inspecting existing gaps, then apply sealant or tape to close them tightly. If you’re working with batt or roll insulation, ensure that all edges are snugly fitted and sealed. Remember, sealing is not just about stopping drafts; it’s about maintaining a consistent thermal barrier that maximizes the performance of your ceiling insulation between floors.

- Identify all potential leak points, including electrical outlets, vents, and duct penetrations.

- Seal each gap with appropriate, weather-resistant materials—think of it as giving your home a protective suit.

- Double-check the sealed areas after installation to confirm no cracks or holes remain.

In the diverse climate landscape of South Africa, sealing gaps in ceiling insulation between floors becomes even more vital. Coastal regions with high humidity demand airtight seals to prevent moisture build-up, while drier inland areas benefit from meticulous sealing to conserve heat. When combined with proper vapor barriers, sealing gaps ensures your home remains comfortable, energy-efficient, and resilient against the unpredictable elements.

Maintaining Ventilation – Balancing insulation with adequate airflow to prevent mold

Achieving a harmonious balance between insulation and ventilation is vital to preventing the silent threat of mold and moisture buildup when installing ceiling insulation between floors. Too often, homeowners focus solely on thermal protection, overlooking the importance of maintaining adequate airflow. Proper ventilation acts as the lungs of your home, allowing excess humidity to escape and ensuring the internal environment remains fresh and healthy. In South Africa’s diverse climate landscape, this equilibrium becomes even more critical—coastal regions demand airtight seals to combat high humidity, while inland areas benefit from strategic airflow to conserve warmth.

One effective practice is to incorporate ventilation channels or soffit vents that facilitate a controlled exchange of air without compromising the insulation’s thermal integrity. Consider the use of adjustable vents that can be sealed during colder months, ensuring the ceiling insulation between floors performs optimally year-round. An optimal approach involves a layered system: insulation to trap heat, vapor barriers to prevent moisture infiltration, and ventilation pathways to expel humid air. This comprehensive method ensures your ceiling insulation between floors enhances energy efficiency while safeguarding against mold and structural decay.

In essence, maintaining this delicate dance between insulation and airflow requires meticulous planning and execution. It’s about creating a home environment that breathes—where warmth is preserved, and moisture is kept at bay, transforming your living space into a resilient, comfort-driven sanctuary. This nuanced interplay not only maximizes the performance of your ceiling insulation between floors but also elevates your home’s long-term durability against South Africa’s unpredictable weather patterns.

Regular Inspection and Maintenance – Tips for assessing insulation condition over time

Regular inspection and maintenance are the unsung heroes of effective ceiling insulation between floors. Over time, even the best insulation can succumb to wear and tear, settling, or moisture intrusion—turning your thermal fortress into a drafty disaster zone. By routinely assessing the condition of your ceiling insulation, you can catch issues early before they morph into costly repairs or energy drains.

Start by visually inspecting for signs of damage, such as sagging, gaps, or areas where the insulation appears compressed or damp. Don’t forget to check for any visible leaks or mold—these are clear indicators that moisture may be compromising your ceiling insulation between floors. If you spot any of these, it’s time to roll up your sleeves or call in the professionals.

Incorporating an annual or bi-annual inspection routine ensures your insulation performs optimally year-round. During these checks, verify that vents and vapor barriers are intact and functioning correctly. Remember, a well-maintained ceiling insulation between floors maximizes energy efficiency, reduces heating and cooling costs, and keeps mold at bay. Think of it as giving your home a health check—only less invasive and more cost-effective!

To keep your insulation in tip-top shape, consider using a checklist or a simple scoring system—making maintenance feel less like a chore and more like an achievement. After all, a little vigilance today prevents a sweat-inducing, wallet-draining disaster tomorrow!

Cost Considerations and Potential Savings

Initial Investment vs Long-term Benefits – Analyzing energy savings and ROI

Investing in ceiling insulation between floors often appears as a significant upfront expense, yet the long-term benefits can be truly transformative for your home’s comfort and energy efficiency. While the initial cost might raise eyebrows, the return on investment (ROI) gradually reveals itself through reduced heating and cooling bills. In South Africa’s varied climate, this insulation acts as a barrier, ensuring your living spaces stay temperate without over-reliance on energy-hungry systems.

Consider this: the energy savings achieved by proper ceiling insulation between floors can amount to as much as 30%. Over time, these savings compound, translating into lower utility bills and a smaller carbon footprint. It’s a compelling calculus—an initial investment that pays dividends with consistent comfort and financial relief. When evaluating costs, it’s essential to weigh the expense of installation against the potential for long-lasting efficiency and increased property value. Sometimes, the true beauty of ceiling insulation between floors lies in its silent, ongoing contribution to a more sustainable and cozy home environment.

Tax Credits and Incentives – Availability of government rebates and support

The true cost of ceiling insulation between floors extends beyond the initial expense—it’s an investment in the future of your home’s comfort and efficiency. In South Africa’s unpredictable climate, the right insulation can drastically cut energy consumption, translating into substantial savings over time. Although the upfront costs might seem daunting, government rebates and incentives are increasingly available to offset these expenses, making energy-efficient upgrades more accessible than ever.

In fact, many homeowners overlook the potential for tax credits or rebates that support the installation of ceiling insulation between floors. These incentives not only reduce the financial barrier but also align with a broader commitment to sustainability. An ordered approach might involve examining local government schemes or energy rebates, which often vary by region and project scope. By leveraging these programs, you amplify the economic benefits of insulation, transforming a simple upgrade into a strategic investment that pays dividends in comfort and savings.

Taking a closer look at potential savings, properly installed ceiling insulation between floors can lower heating and cooling costs by as much as 30%. This reduction not only alleviates the burden on your wallet but also diminishes your home’s carbon footprint. With rising energy prices, such long-term savings become an unavoidable consideration—an unspoken moral obligation to reduce waste and promote sustainability in every corner of your living space.

Effect on Utility Bills – Impact on heating and cooling costs

The financial impact of installing ceiling insulation between floors extends far beyond the initial expense — it’s a prudent investment that can dramatically influence your household’s energy expenditure. In South Africa’s fluctuating climate, where temperatures can swing unpredictably, effective insulation acts as a thermal buffer, reducing reliance on heaters and air conditioners. This translates directly into lower utility bills, often by as much as 30%.

While the upfront costs may seem significant, the long-term savings are compelling. Properly installed ceiling insulation between floors not only curtails heating and cooling costs but also enhances overall home comfort. It’s a strategic move that pays dividends over time, especially when combined with available government rebates and incentives. These financial incentives serve as catalysts, making the decision to upgrade more accessible and financially viable.

In essence, the financial calculus of ceiling insulation between floors reveals a clear advantage: a reduction in utility bills that can justify the initial investment and contribute to a more sustainable lifestyle. As energy prices continue to climb, such upgrades become less of a luxury and more of a necessity — a step toward smarter, more efficient living in South Africa’s diverse climate zones.

Common Challenges and Solutions

Dealing with Limited Space – Choosing appropriate insulation materials and techniques

Limited space often presents a formidable obstacle when installing ceiling insulation between floors, especially in older South African homes where architectural constraints are common. The challenge lies in selecting insulation materials that not only deliver optimal thermal and acoustic benefits but also conform to the tight confines of existing structures. In such scenarios, spray foam insulation emerges as an exemplary choice—its ability to expand and fill irregular gaps ensures comprehensive coverage without compromising precious headroom. Conversely, fiberglass batts or mineral wool, with their thinner profiles, can be tailored to fit snugly in narrow cavities, providing a practical solution without sacrificing performance.

Addressing these spatial limitations often requires a nuanced approach—combining innovative techniques with a keen understanding of the building’s structural nuances. For instance, blown-in cellulose or fiberglass insulation can be swiftly and effectively installed in confined spaces, filling voids that traditional methods might leave behind. By meticulously sealing gaps and choosing the right insulation material, homeowners can surmount the challenges of limited space, ensuring that their ceiling insulation between floors not only enhances comfort but also adheres to local building standards and energy efficiency mandates. The key is to balance technical insight with practical ingenuity—transforming spatial constraints into opportunities for smarter insulation solutions.

Managing Moisture and Condensation – Preventative measures to avoid dampness and mold

Moisture and condensation pose significant challenges in maintaining effective ceiling insulation between floors. Excess humidity creates a perfect environment for dampness, mold, and structural damage. Preventative measures are crucial to safeguard both the insulation and the home’s integrity. Proper ventilation, combined with high-quality vapor barriers, can dramatically reduce moisture buildup.

In areas with high humidity, sealing gaps and cracks around the ceiling helps prevent warm, moist air from infiltrating the insulation layer. For optimal results, consider using vapor retarders that are compatible with ceiling insulation between floors.

- Ensure proper airflow by installing vents or exhaust fans.

Regular inspections are essential to catch early signs of moisture intrusion. Addressing these issues swiftly keeps insulation dry, preserves its thermal performance, and prevents costly repairs down the line. When moisture is managed effectively, ceiling insulation between floors continues to deliver its full benefits—keeping homes warm, dry, and mold-free.

Addressing Structural Limitations – Working around existing ceiling frameworks

Dealing with the structural skeleton of a home is often the most daunting challenge when installing ceiling insulation between floors. Existing ceiling frameworks, with their tangled web of beams and joists, can seem like an ancient labyrinth, resisting the gentle embrace of insulation. Yet, these structural limitations need not be insurmountable barriers. Instead, they become opportunities to innovate—working around the bones of the building without compromising its integrity.

One of the most effective solutions involves tailoring insulation materials to fit snugly within the confines of the existing framework. Flexible batt insulation or blown-in cellulose can adapt to irregular spaces, filling gaps where rigid panels might falter. For homes with limited headroom, spray foam insulation offers a seamless, conforming layer that adheres directly to the underside of the floor above, sealing every crevice with precision.

In some cases, a strategic approach is essential:

- Identify and reinforce weak points in the ceiling structure.

- Use lightweight insulation materials that won’t add undue stress to the existing framework.

- Install vapor barriers carefully to prevent moisture infiltration without disrupting the structural flow.

Every challenge posed by the architectural skeleton becomes a puzzle—one that, when solved with expertise and care, ensures the ceiling insulation between floors performs its silent duty of thermal regulation and soundproofing, defying the limitations of the old bones that hold the home together.

Choosing the Right Insulation for Your Needs

Factors Influencing Material Selection – Climate, budget, and home type considerations

Choosing the right ceiling insulation between floors hinges on a delicate balance of factors that influence material selection. Climate plays a pivotal role; in South Africa’s varied weather, insulating materials must adapt to both hot summers and chilly winters. For instance, mineral wool offers excellent thermal regulation, while spray foam provides superior airtight sealing in colder regions. Budget considerations also shape decisions—cost-effective options like cellulose blown-in insulation can deliver impressive performance without breaking the bank.

Home type further influences the choice, whether it’s a compact apartment or a sprawling double-storey home. For limited space, lightweight batt or roll insulation might be the best fit, whereas larger structures benefit from spray foam or blown-in techniques. When selecting ceiling insulation between floors, one must also evaluate existing insulation levels and structural constraints to ensure optimal performance. Ultimately, tailoring insulation materials to specific environmental and structural needs guarantees enhanced comfort and energy efficiency.

Eco-Friendly and Sustainable Options – Green insulation materials and their benefits

Choosing eco-friendly and sustainable options for ceiling insulation between floors is more than just a trend; it’s a meaningful step towards reducing our carbon footprint and fostering healthier living spaces. Green insulation materials such as recycled cellulose, sheep’s wool, and plant-based foam not only minimize environmental impact but also offer outstanding thermal and soundproofing qualities. These materials are often biodegradable, non-toxic, and harvested responsibly, making them ideal for environmentally conscious homeowners in South Africa.

Opting for sustainable insulation can also translate into long-term savings. Many green options provide superior insulation performance, which means better temperature regulation and reduced energy bills. Additionally, eco-friendly ceiling insulation between floors can improve indoor air quality by avoiding harmful chemicals found in some traditional materials. When considering environmentally responsible choices, it’s vital to look for products that meet local standards and certifications, ensuring both sustainability and compliance.

Incorporating green insulation into your home not only nurtures the environment but also elevates your living comfort—proof that caring for the planet can go hand in hand with creating a cozy, energy-efficient home. Embracing these options is a heartfelt commitment to future generations, blending innovation with our deep-rooted respect for nature’s precious resources.

Safety and Certification – Ensuring materials meet safety standards

Choosing the right ceiling insulation between floors isn’t just about stuffing some fluffy material into your ceiling cavity and calling it a day. It’s about ensuring your home’s safety, compliance, and overall comfort — all while keeping the environment in mind. South African regulations are strict, and ignoring safety standards could turn your cozy haven into a potential hazard. That’s why verifying that your insulation materials meet local safety certifications is essential. Certificates from reputable authorities guarantee that the materials are non-toxic, fire-resistant, and suitable for our unique climate.

When selecting insulation for between floors, look out for products with clear safety labels and certifications. These often include compliance with South African building standards and eco-certifications, which assure you that your choice isn’t just good for the planet but safe for your loved ones too. Remember, an insulation material’s safety isn’t just about fire resistance; it’s also about avoiding harmful chemicals that could compromise indoor air quality or cause health issues over time.

To streamline your decision, consider this simple checklist:

- Check for local safety certifications and compliance standards

- Ensure materials are non-toxic and eco-friendly

- Verify fire safety ratings and moisture resistance

By prioritizing safety and certification, you’re not only protecting your home and family but also ensuring that your ceiling insulation between floors adheres to South Africa’s rigorous standards. After all, a well-insulated home is only as safe as the materials used to insulate it!